After buying our Sequoia last weekend and registering the car I need to replace the license plates.

Unfortunately one of the bolts was rusted and I also don't think they thread the bolt correctly when they installed the plate. I tried removing it but the phillip head got striped but was able to get a hold of the bolt head with a pair of pilers. It started to turn but after about a full turn the bolt broken, and nothing was sticking out.

I attempted to remove it using an extracting bit, but the center punch hole I guess wasn't good enough and the hole I drilled ended up not being in the center. Thus I am able to remove it from that method.

I am curious what are my options? This is what I am think:

1) Am I able to get to the back side of the bolt through the rear panel? If so, what is the process to remove the rear panel? I think it is fairly straight forward but I don't know how to get to the bolt on the strap? Do I just pull off the cover?

2) Completely drill out the bolt and then replace the whole thread piece. Although I don't think I would be able to do this.

3) Drill into the rear hatch and use the bottom two screws, this way I would have 1 bolt up top, and 2 screws below.

4) Glue a magnet into the hole and use a high strength magnet to attach the two.

Or just bite the bullet and take it to the dealership to deal with.

Unfortunately one of the bolts was rusted and I also don't think they thread the bolt correctly when they installed the plate. I tried removing it but the phillip head got striped but was able to get a hold of the bolt head with a pair of pilers. It started to turn but after about a full turn the bolt broken, and nothing was sticking out.

I attempted to remove it using an extracting bit, but the center punch hole I guess wasn't good enough and the hole I drilled ended up not being in the center. Thus I am able to remove it from that method.

I am curious what are my options? This is what I am think:

1) Am I able to get to the back side of the bolt through the rear panel? If so, what is the process to remove the rear panel? I think it is fairly straight forward but I don't know how to get to the bolt on the strap? Do I just pull off the cover?

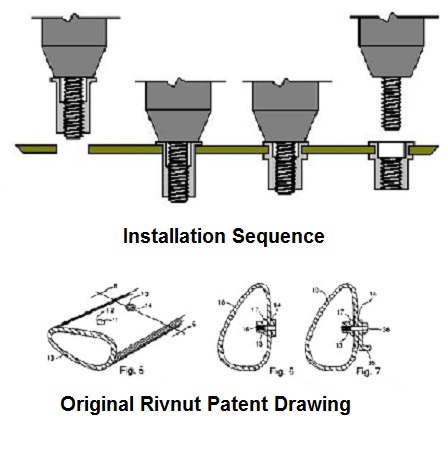

2) Completely drill out the bolt and then replace the whole thread piece. Although I don't think I would be able to do this.

3) Drill into the rear hatch and use the bottom two screws, this way I would have 1 bolt up top, and 2 screws below.

4) Glue a magnet into the hole and use a high strength magnet to attach the two.

Or just bite the bullet and take it to the dealership to deal with.